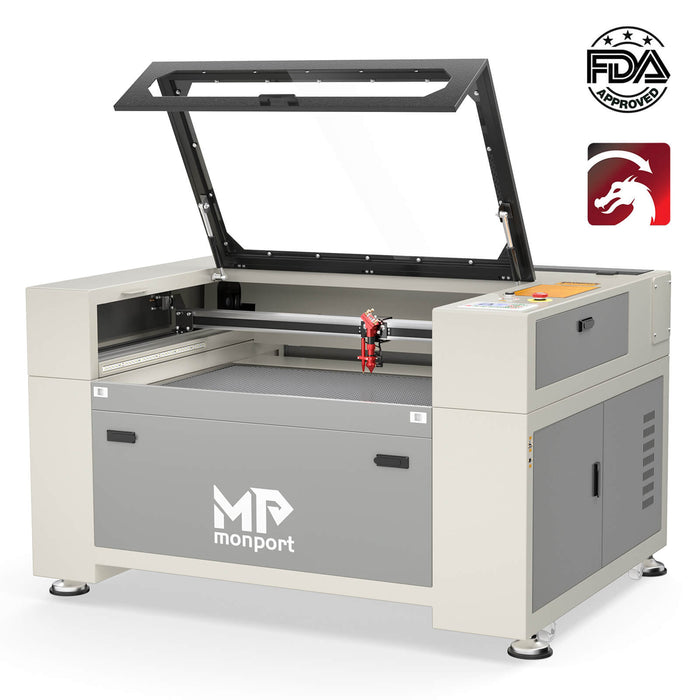

CO2 Laser Machine

CO2 Laser Machine

CO2 Laser Machine is a versatile piece of equipment that can be used to cut and engrave various materials. It can also be used for medical resurfacing and artistic engraving.

The machine operates by using a gas mixture contained in a tube with nitrogen, helium and carbon dioxide. An electric field energizes the molecules of nitrogen, which then pass the energy on to the CO2 molecules.

High Precision

The high precision of CO2 laser cutting machines makes them ideal for use in serial production. They can achieve a minimum error of only a few hundredths of a millimeter along the cutting seam. This can translate to savings in raw materials in mass production.

Unlike other types of laser cutters, CO2 lasers do not produce any reaction loads when they cut. This allows them to be used on delicate materials such as living tissue or metal, without damaging them. This high level of precision CO2 Laser Machine also makes CO2 lasers an ideal choice for medical applications, such as otolaryngology, where they can be used to treat the larynx or airway lesions.

A CO2 laser works by first heating the material until it melts, then using a jet of high-pressure gas like nitrogen to blow the molten material away from the area being engraved or cut. This method allows the laser to heat a larger area of the workpiece than other methods and reduces the power necessary to achieve the same result.

The laser’s beam can be moved quickly and precisely with highly accurate servo motors. This allows for the laser to be used in a wide range of applications, from cutting and engraving to etching and marking. It can even be used to remove industrial rust from metal.

Easy to Operate

The CO2 laser works by directing an intense, highly focused beam of light at the material to be cut. This results in the material melting and vaporizing. A computer is used to control the beam of light and direct it onto the material to be cut. This allows the operator to remain hands-free during the process. It also eliminates the need to perform multiple pre-cuts. The resulting edge quality is much finer than that of traditional methods.

The laser beam is produced inside the primary glass laser tube which is filled with CO2, N2, and helium gases. This tube is surrounded by the resonator, a circular glass tube with one end covered with a gold-plated total reflection mirror and the other with a partial reflection mirror made of Germanium or Gallium Arsenide. When an electric current passes through the resonator, the gas molecules become ionized and electrons are energized. The carbon atoms then emit photons that are detected by the laser mirror.

The resonator tube is surrounded by a cooling system which uses a helical tube to transport heat away from the primary laser tube. This helps to keep the temperature in the resonator at an optimal level and keeps it working properly. The CO2 laser can produce a powerful beam of light with minimal energy input, making it safe for use in health applications such as otolaryngology (ear, nose, and throat conditions) and airway lesions.

Wide Range of Materials

CO2 lasers can cut and engrave a variety of materials including metal, wood, plastic, and tissue. This is because they emit a beam with a wavelength that can penetrate through the material and cause an effect on it’s electrons.

The process starts with the resonator, a cylindrical glass tube filled with carbon dioxide, nitrogen and helium. An electric field energizes the nitrogen molecules, causing them to transfer energy to the CO2 gas molecules in the resonator. This causes the CO2 molecules to become excited and emit photons. The photons travel to a mirror on one end of the resonator and a lens on the other. The lens focuses the photons into a narrow beam, increasing power and accuracy.

Lasers can be continuous or pulsed, depending on the application and required result. For example, continuous lasers produce ablative skin treatments with a smooth surface while pulsed lasers can be used to shrink dilated blood vessels in the skin.

Both continuous and pulsed lasers are available with a variety of wavelengths. You can even add a fiber laser to a CO2 machine for additional marking capabilities, without manually changing the laser tubes and lenses. This allows you to take advantage of the unique abilities of each laser source and saves on replacement turbines and glassware. This is particularly helpful when working with high volume jobs.

Reduced Maintenance

CO2 laser machines have many parts that require regular cleaning and maintenance, including mirrors, lenses and turbines. If these are not properly cleaned and maintained, they will eventually break down, leading to costly repairs. This is why it’s important to follow your machine manufacturer’s recommended maintenance schedule.

This includes cleaning the viewing windows with a mild cleaner and a lens cloth. In addition, it’s essential to clean the cooling system’s water filters and change them as needed. If the coolant is not filtered, it can cause damage to the lens and shorten its lifespan. In addition, it can also lead to odor and smoke in the machine.

Additionally, if the cooling water CO2 Laser Machine is not clean, it can cause dirt and debris to accumulate on components like the laser’s charged cathodes. In turn, this will affect the machine’s performance and result in a lower level of precision.

In contrast, fiber lasers have fewer vulnerable pars and require less maintenance. It’s also worth noting that fiber lasers consume three times less energy than a CO2 machine when cutting the same material. This translates to lower operating costs.